Innovative Material Mainly Made of Limestone

Application Made from LIMEX Pellet

Tested in Kemas

Earth provides enough to satisfy every man’s needs, but not every man’s greed. Humans take so much from the earth. Yes, earth loves us – let us love it back. Make better healthy earth by using more bio-degradable and natural materials. KEMASPKG starts with 60% Limestone (LIMEX) Packaging and BioPaint. If you need further info, please click here.

We are come to the following conclusion of LIMEX Strength Poin :

- Cheap compared to ABS

- Abundant in availability.

- Recyclable

- Can use regular injection molding tools

- Good chemical resistance to water, oil, sunscreen. Thus, suitable for cosmetic packaging.

- Good hardness and strength.

- Can satisfy most cosmetic packaging specifications in lipstick, compact, and jar.

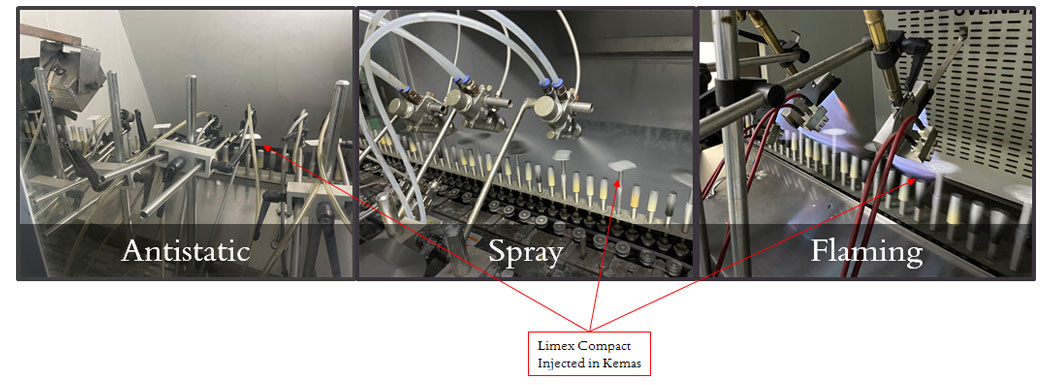

- Can be decorated with masterbatch color and post molding decorations such as printing, hot-stamping, and heat transfer foil

- Does not shrink as much as PP. Therefore, less sink mark aesthetic issue.

- Very high specific gravity (~1.5), therefore package feels heavy and luxurious naturally

- High possibility on Molding on Existing Mold (replacing current materials) (Case by Case Testing)

Challenges and on-going development:

- Lower flexibility. Nonetheless, we are currently testing another grade that is more flexible (to be used for application that needs flexibility) (Made in Japan)

Kemas Molding Test (limex Material)

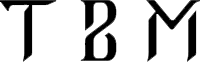

KEMAS UV COATING TEST (limex Material)

KEMAS DECORATION PROCESS TEST (limex Material)

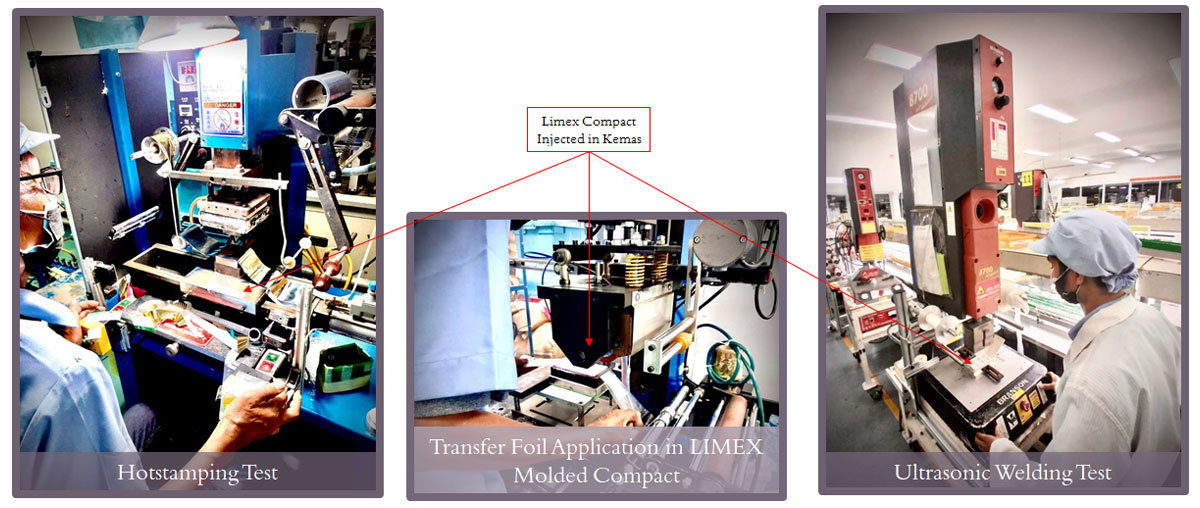

Limex Testing

Jl. Rawaterate II No.16

Kawasan Industri Pulo Gadung

Jakarta Timur, Jakarta 13930

Indonesia

+62-21-4608847

+62-21-4608848

+62-21-4603720

+62-21-4608845 (fax)